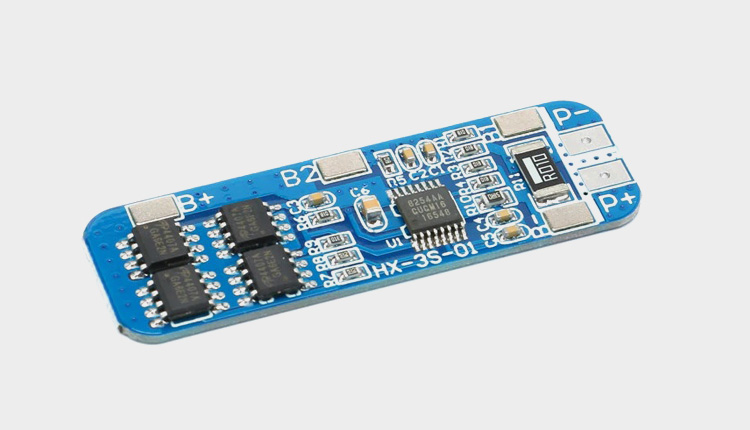

Lithium Battery Protection Circuit

2021-07-27 11:07:28 Pageview: 2909

Lithium Battery protection circuit, its function that protects rechargeable battery, sustains its safety and consistence during charge and discharge, plays a important part in the whole battery circuit, e.g. Lithium ion Battery, like mobile battery, includes cell, PCM and case.

Main function of PCM,

a. Over charge protection, stop charge once reach to certain voltage, in another word, MOS that controls overcharge be cut off, stop charge.

b. Over discharge protection, stop load discharge when voltage drop to certain voltage, MOS that controls over discharge be cut off, stop discharge, it’s opposite with over charge monitor.

c. Over current protection, stop load discharge when over current too large, aim to protect battery and MOS, make sure the safety of battery when working; and PCM will auto recover.

d. Short circuit. Principle as below, protect IC, core of protect chip, judge from sample Battery Voltage, send control message to MOS, manage chip; MOS, switch of PCM circuit.

Typical PCM circuit, take single protection circuit (DW01+p) for example.

PCM classified

a. Material, gold/tin plating

b. Battery, single, double, multi PCM

PCM market

Demand of global market about 100 million per month

a. A grade market, 40 million per month, main protect IC manufacturer SEIKO, RICOH, MITSUMI; MOSFET manufacturer, SANYO, AO.

b. B grade market, 40 million per month, main protect IC manufacturer FORTUNE, NEOTEC, VIMICTO; MOSFET manufacturer, SAMHOP, CETSEMI, SOUTHSEASEMI, MAXTEK, ANPEC.

c. C grade market, 20 million per month, main protect IC manufacturer SILAN, SINGEN, JWK; MOSFET manufacturer ZHUHAI NANKER, SINGEN, JWK.

- Prev Article: ICR18650-22F 2200mAh Samsung Cell

- Next Article: Distinguish Carbon and Alkaline Batteries